Bunker Hill Mine successfully commissions water pre-treatment plant

KELLOGG — The Bunker Hill Mining Corporation announced on Thursday the successful commissioning of its water pre-treatment plant, designed to significantly improve the quality of mine water discharge from the Bunker Hill mine. This supports a sustainable restart of mining operations based on modern zero-footprint techniques designed to enhance the quality of the environment.

“Managing our mine water discharge is an essential part of a strategy designed to rapidly re-start the Bunker Hill mine as a low cost, modern, and sustainable operation," said Sam Ash, CEO of Bunker Hill Mining. "Together with our high-grade silver exploration program and delineation of our maiden NI 43-101 compliant resource, the successful commissioning of our pre-treatment plant marks another key milestone in achieving this goal and highlights our new team’s technical capabilities. We remain on track to deliver our PEA by early Q2 2021.”

THE WATER MANAGEMENT PROGRAM

The company began its water management program in September 2020 with the goal of improving the understanding of the mine’s water system and enacting immediate improvement in the water quality of effluent leaving the mine for treatment at the US Environmental Protection Agency’s (“EPA”) Central Treatment Plant (“CTP”). The recently commissioned pre-treatment system achieves this goal by reducing significantly the amount of treatment required at the CTP, and the associated costs, before the mine water is discharged into the south fork of the Coeur d’Alene River. The company’s new pre-treatment system is removing over 70% of the metals from water before it leaves the mine, with the potential for further improvements.

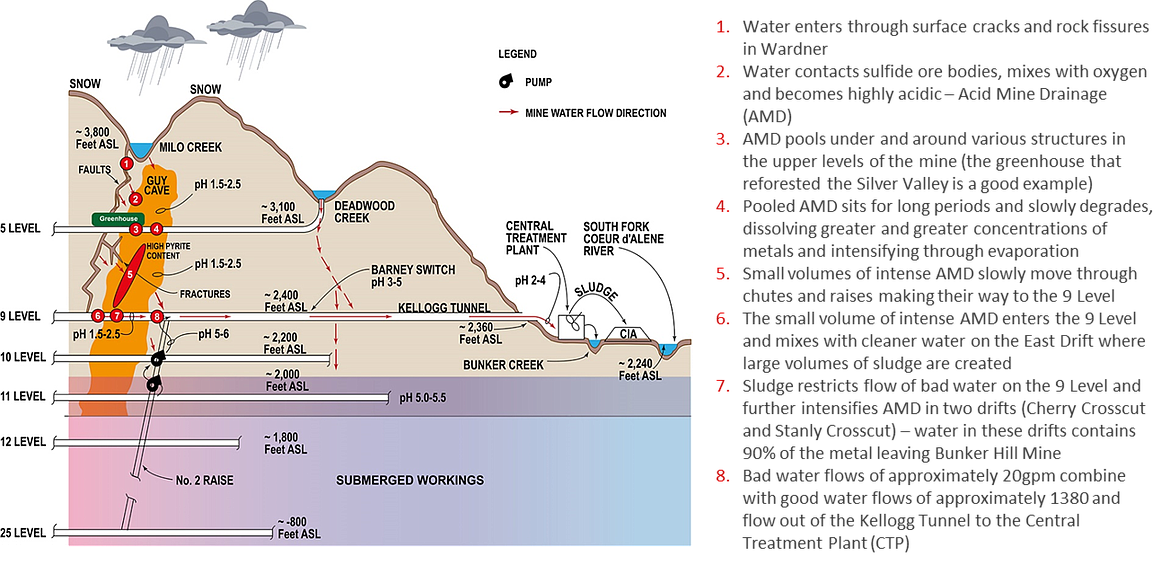

Informed by historical research provided by the EPA, the company initiated a study of the water system of the mine to:

1.Identify of the areas where Sulphuric acid (Acid Mine Drainage, or “AMD”) is generated in the greatest and most concentrated quantities.

2.Understand the general flow paths of AMD on its way through and out of the mine as it travels to the Central Treatment Plant.

Having completed this work, which largely confirmed the conclusions reached by the EPA’s own studies, the company started by removing any obstacles that created pooling of acid water. The pooling of acidic mine water generally provides conditions that degrade and worsen water quality over time (see Figure 2 below). Eliminating these obstacles reduces the time that water spends in the mine and thereby improves its quality. These studies also allowed the company to identify areas where the acidic water mixed with cleaner water. It was discovered that approximately 85% of the metal load in the mine effluent is contained in only 1% of the water flow, allowing the company to isolate and treat these intense AMD zones in ways that further reduce the downstream treatment requirements and costs at the CTP.

By keeping the acidic water from mixing with the cleaner water, this allows Bunker Hill to focus on the treatment of a smaller stream of effluent, thus reducing the cost and scale of treatment. As shown in Figure 1, the company achieved this by creating a channel system on the four levels of the mine where AMD production is greatest. These channels divert the AMD into to a pipe system that keeps them separate from the cleaner water.

The AMD then flows from the upper levels of the mine via these pipes to the Kellogg Tunnel, on the 9 Level. From there it is piped to the new treatment facility where a concentrated lime slurry is added to the AMD flow to increase the water’s pH to a neutral state and enable the precipitation of metals from the water before it leaves the mine.

WATER PRE-TREATMENT PLANT RESULTS

Results from the testing of mine effluent discharged from Kellogg Tunnel on Feb. 2 indicate a significant reduction in its metal content when compared to previous time periods. Lab testing conducted by Silver Valley Analytical, Inc. an environmental testing laboratory based in Kellogg, indicate a 71% reduction in zinc in the course of only a couple days of operation. Results for cadmium indicate similar results with dissolved levels reduced by 72% from the previous month.

Working with the EPA and other stakeholders, the company will continue to monitor the mine’s internal water system and the quality of water discharged from the Kellogg Tunnel as a routine part of its environmental management plans, whilst seeking out ways to further improve the sustainability of its operations and development plans.